Bringing a new product to market requires more than just a great idea – it demands precise engineering, quality manufacturing, and a proven process to ensure success. For over 100 years, Amerequip has helped OEMs transform concepts into market-ready products through comprehensive design and manufacturing solutions. If you’re struggling with the details of how to manufacture your own product, Amerequip can help.

Today we’re exploring the process of a partnership with Amerequip and showing how we move your production forward.

Go from sketch to skid: Contact the team at Amerequip for expert engineering and manufacturing to turn your concepts into reality.

The 4 Phases of How to Manufacture Your Own Product with Amerequip

Starting Your Manufacturing Journey

The path from concept to finished product begins with understanding your specific needs and market requirements. Amerequip’s team works closely with OEMs in the construction, lawn and garden, and industrial equipment sectors to define project parameters and establish clear objectives. Our exclusively developed 6-phase project management process ensures thorough organization, planning, and control of your program from initial development through market introduction.

During these early stages, our team collaborates with yours to understand not just the technical requirements, but also your business goals, timeline constraints, and cost targets. This comprehensive approach helps ensure that the final product meets all specifications while maintaining your competitive edge in the market.

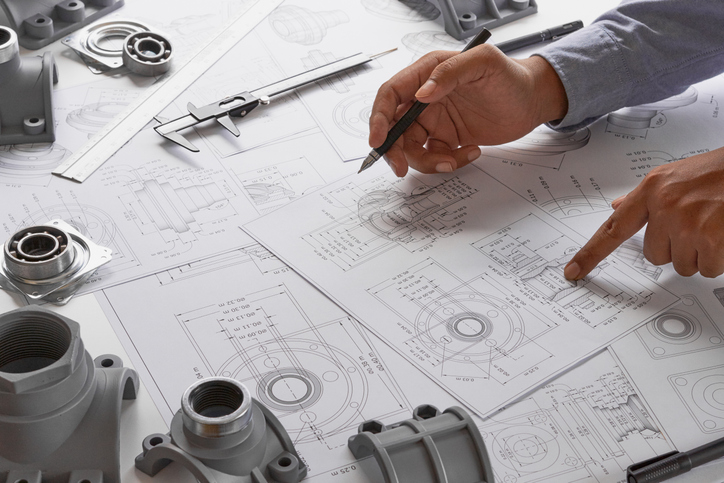

Design & Engineering Phase

Once project parameters are established, our independent, on-site design and engineering team springs into action. Using advanced CAD software packages including CREO Direct, CREO Parametric, and SolidWorks, our engineers develop detailed product designs that can be seamlessly integrated with your existing systems.

Prototyping and testing are critical steps in our process. Our dedicated prototype shop provides rapid turnaround for fabrication and assembly, helping reduce time to market. Products undergo rigorous validation testing in our state-of-the-art facilities, including:

- Strain gauge testing

- Durability testing under various conditions

- Full function implementation testing

- Hydraulic system validation

- Testing across 40+ acres of varying terrain in temperature extremes from -20°F to 100°F

Production Planning

With validated designs in hand, our team develops comprehensive manufacturing plans that optimize efficiency and quality. We utilize lean manufacturing principles and advanced planning tools to ensure smooth production flow. Our engineering and manufacturing teams collaborate closely to ensure designs are optimized for manufacturing efficiency while maintaining product integrity.

Quality control planning is integrated throughout the process, with detailed control plans and inspection protocols established before production begins. Our supplier quality engineers work with our supply chain partners to ensure all components meet our exacting standards.

Manufacturing Excellence

As a vertically integrated manufacturer, Amerequip handles every aspect of production in-house, ensuring complete control over quality and timing. Our comprehensive capabilities include:

- Precision laser cutting with six 4500-watt Mitsubishi Lasers

- Advanced forming operations with precision WILA tooling

- State-of-the-art robotic and manual welding in our 75,000 sq ft weld shop

- Superior painting process, including acid pickling bath and e-coat base paint

- Flexible final assembly areas designed for quick changeovers

- Custom hydraulic cylinder manufacturing with less than 0.20% warranty rate

Throughout production, our ISO 9001:2015 certified processes and Six Sigma methodologies ensure consistent quality. Our track record speaks for itself, with over 99% on-time delivery rates and total warranty rates below 0.5%.

Take the Next Steps with Amerequip

Working with Amerequip means gaining a true manufacturing partner committed to your success. Our vertical integration capabilities eliminate the complexity of managing multiple vendors, while our engineering expertise helps optimize your products for market success.

For more than a century, we’ve been a proud partner for A-list companies across several important industries. Our expertise delivers consistent, high-quality results, and our culture ensures we’ll continue to work to improve and better meet your needs in the future.

Ready to bring your product to life? Contact our team to discuss your project requirements. We’ll guide you through our process and help develop a manufacturing solution tailored to your specific needs. Because your reputation is our reputation, we never compromise on quality or performance.